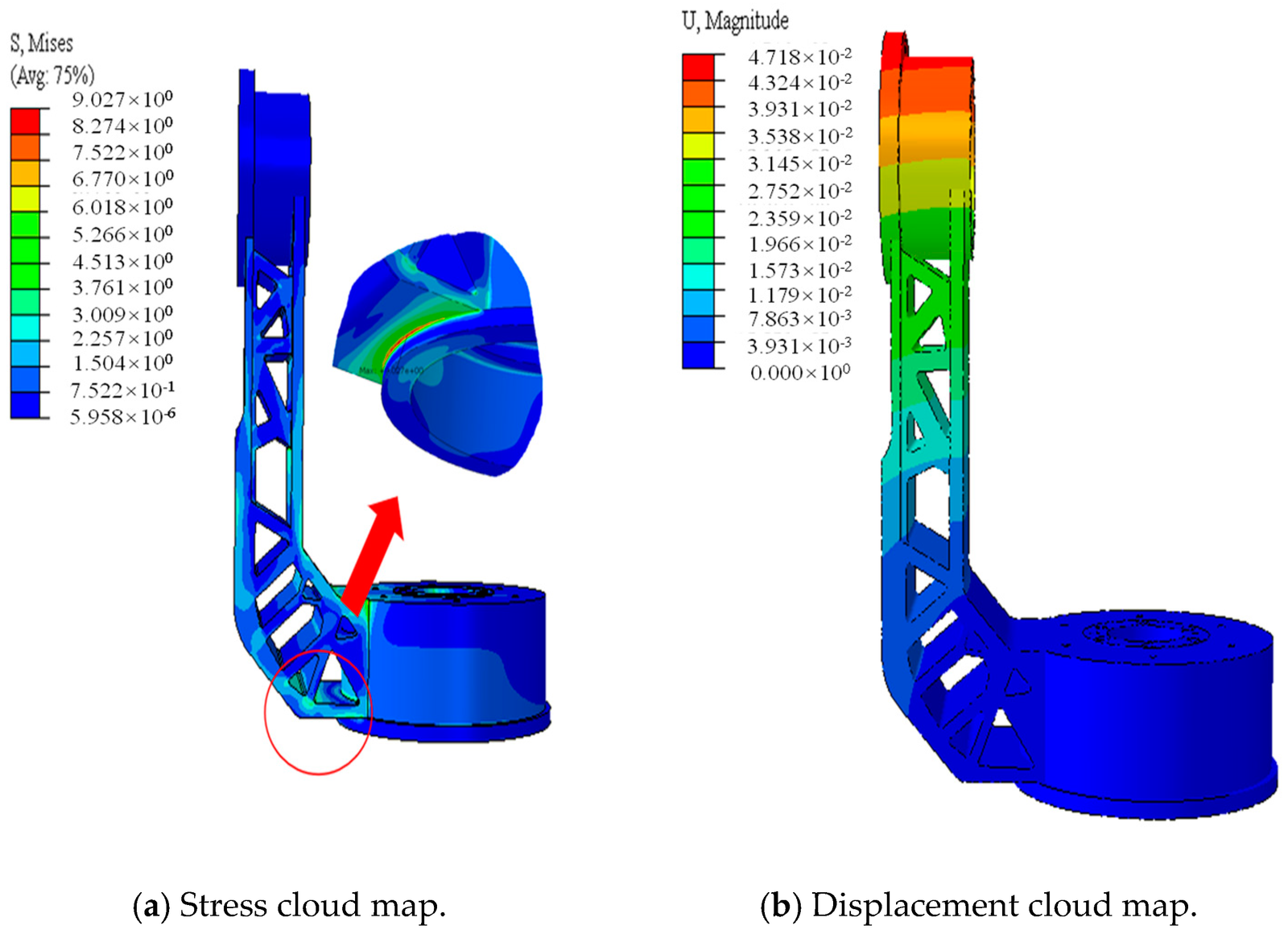

The Topology Optimization of Support Bracket project focuses on reducing weight and improving strength by using advanced computational algorithms to optimize material distribution. By analyzing load paths, constraints, and safety factors, this project delivers a lightweight yet robust bracket design ideal for automotive, aerospace, and industrial applications. The result is maximum efficiency with minimal material usage, promoting both performance and cost-effectiveness.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved