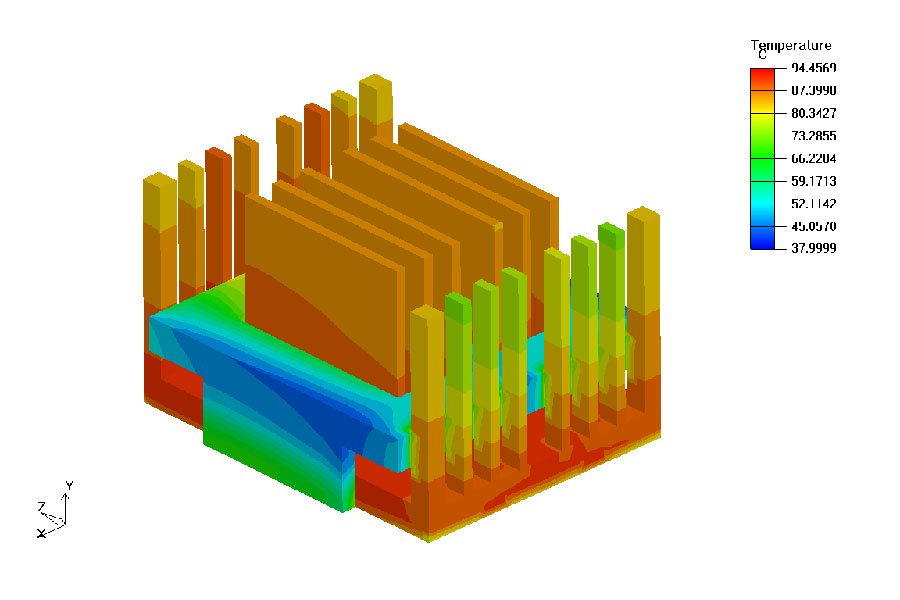

The CFD Analysis of Heat Sink project evaluates and optimizes heat‑sink performance using Computational Fluid Dynamics to predict airflow, temperature distribution, and pressure drop. By virtually testing fin geometry, spacing, and materials, you can cut prototypes, lower costs, and reach a cooler, more reliable design faster.

Key outcomes include lower thermal resistance (Rθ), reduced hot spots, and balanced pressure drop, ensuring the best trade‑off between cooling and fan/pumping power.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved