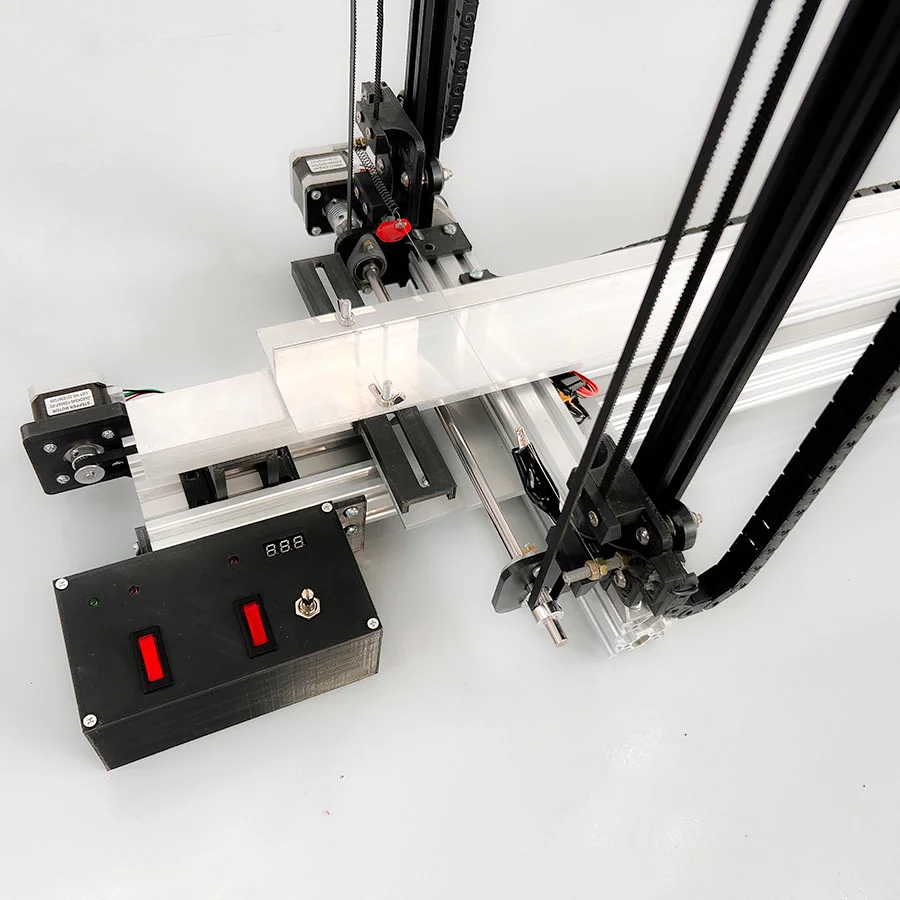

A CNC Foam Cutter with Hot Wire is a precision cutting machine that uses a heated resistance wire to cut thermocol (EPS), foam, and polystyrene into complex shapes. Controlled by G-code, the hot wire melts through the foam smoothly, enabling accurate and dust-free cutting for prototyping, architectural models, and signage.

This project is ideal for engineering students, model makers, and fabrication workshops who need custom foam designs with high precision.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved