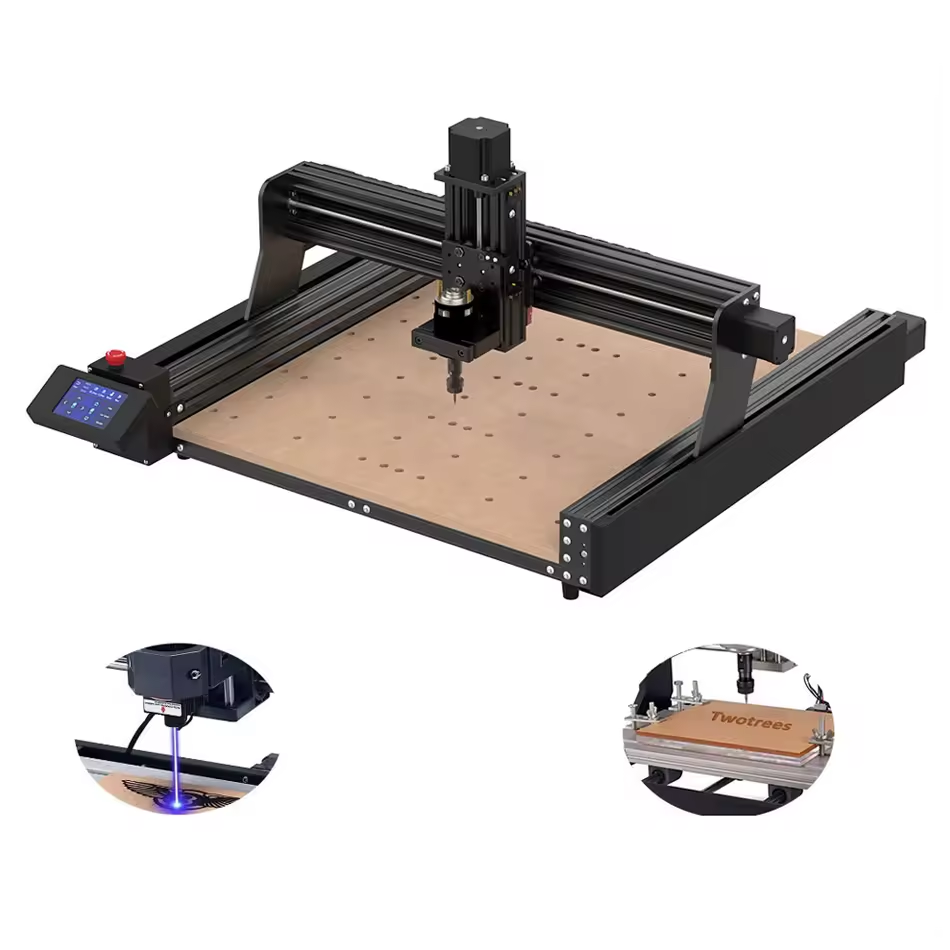

A CNC PCB Milling Setup is a precision machine designed to create Printed Circuit Boards (PCBs) by removing unwanted copper from a copper-clad board. Instead of using chemical etching, this method relies on a computer-controlled milling tool to engrave circuit traces directly, making it an eco-friendly and fast way to prototype electronics.

This setup is ideal for engineering students, electronics hobbyists, and small-scale manufacturers who want in-house PCB prototyping without outsourcing.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved