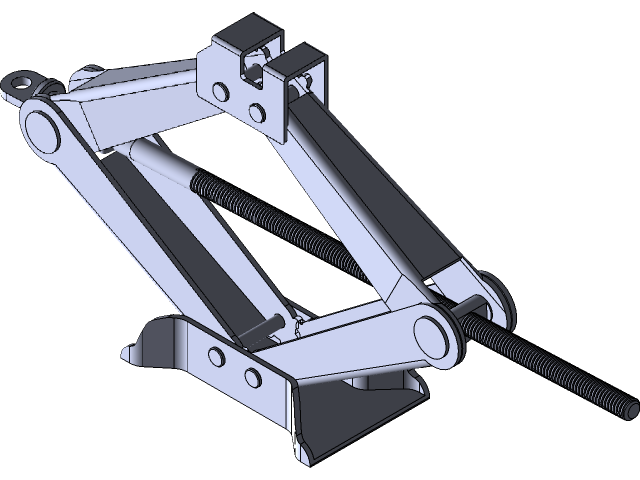

A compact electro-mechanical lifting jack that uses a trapezoidal lead screw + nut driven by a DC/AC gearmotor. Ideal for lifting/positioning machines, cars (demo), fixtures, and as a mechatronics project—precise, self-locking, and easy to control with limit switches.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved