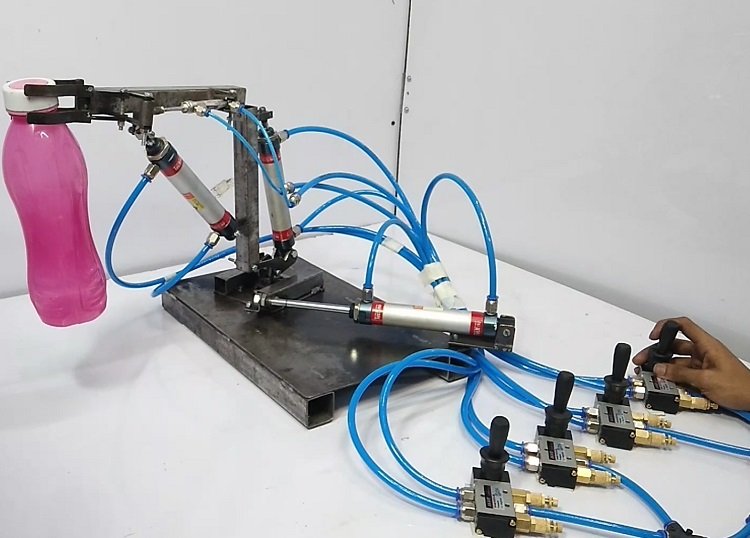

A Pick and Place Robotic Arm is an automated system designed to lift, move, and position objects from one location to another with high precision. It is commonly used in manufacturing, packaging, and assembly lines to improve productivity and reduce manual labor. The arm is controlled using microcontrollers or PLCs and can be programmed for repetitive tasks. Its fast operation and accuracy make it ideal for industrial automation.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved