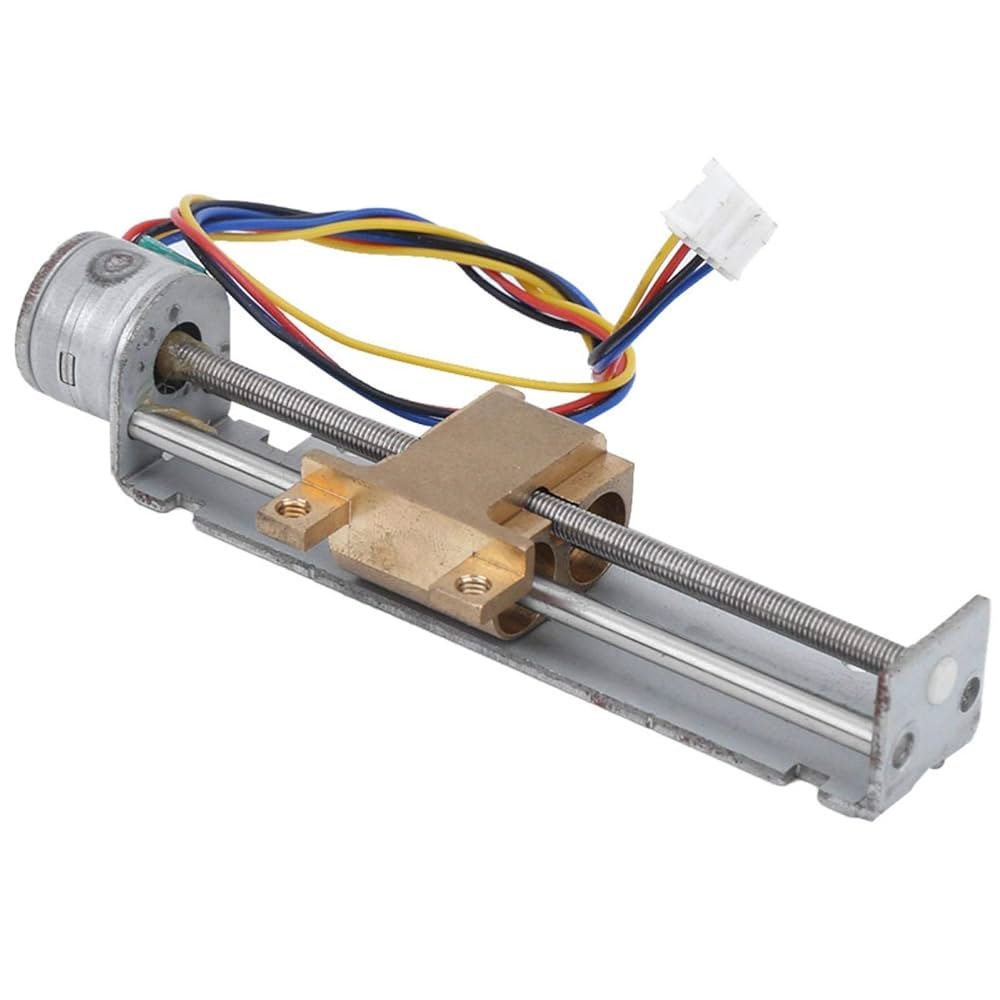

A Stepper Motor Driven Drill Table is an automated drilling platform where the drill head or the worktable is precisely moved using stepper motors. This setup allows accurate hole positioning, consistent drilling depth, and repeatable patterns without manual alignment. It’s an ideal project for automation learning, CNC principles, and precision manufacturing.

Got Questions About Your Final Year Project?

Got Questions About Your Final Year Project? We help engineering students submit their projects stress-free – with models, reports, and full guidance.

No stress. No confusion. Just working models, ready reports, and full support.

Pricing varies by stream and complexity. Get in touch for a quick quote.

Yes, our projects have been accepted by 1000s of students across India.

You get a working model + documentation + PPT + viva support.

© 2015 – 2024 Themexriver I All Rights Reserved